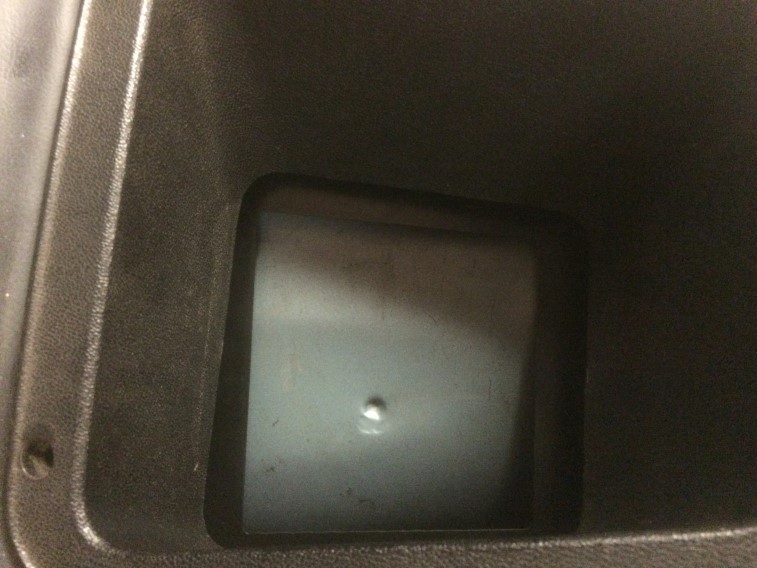

I am about a week overdue with this post, but here is the latest on the progress of re-doing the 4-speed shifter hump.

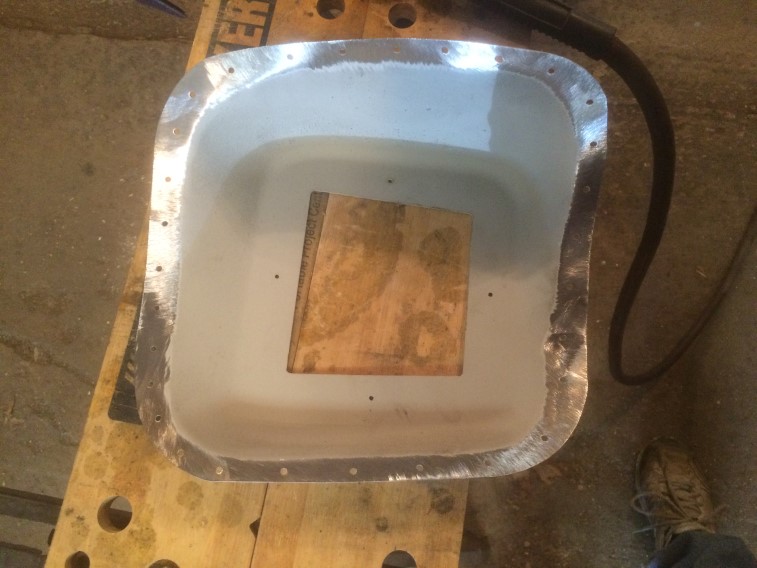

Started by using magnets to hold it in place while I traced the opening on the bottom of the patch:

Compared it to one of the original pieces I kept when cutting it the first time:

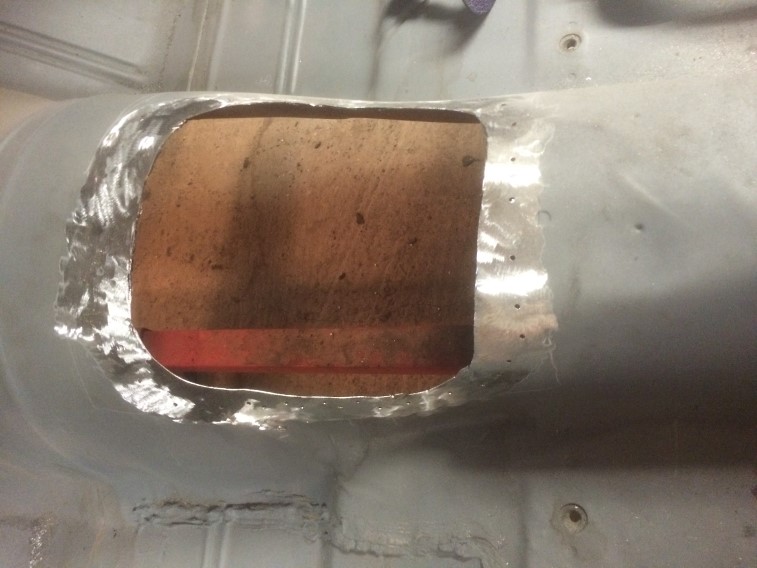

There is a lip that sticks out on the drivers side I needed to deal with. So the fun begins with measuring, marking, and trimming:

These metal marking pens are great!:

Then spent a lot of time measuring, marking, and trimming little-by-little:

I was also marking on the shell the placement of the patch for a reference:

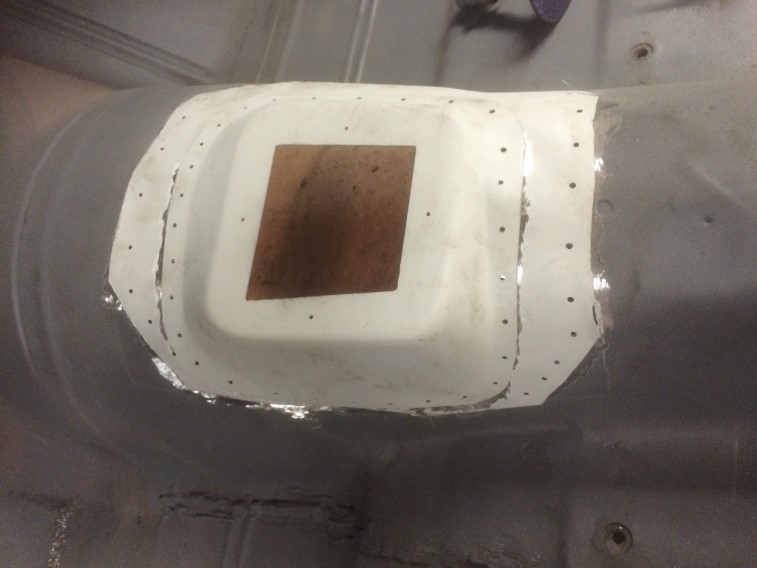

Then I was worried that I might have cut too much for the hump to rest on, so a quick trial fit:

Then I had to bend and hammer the patch and floor so it was snug:

I determined that the magnets wouldn’t do the job, so the plan is to rivet it in place, then patch in the shifter hump – riveting that in then using body adhesive next Spring with the rivets to complete the job.

Now it is on to some pre-winter non-car projects, so the car work is on hold. There won’t be a lot to do over the winter, but a little here-and-there.