Made a little progress this week. First an picture of the firewall after cleaning:

Still need to attack the inside of the trunk:

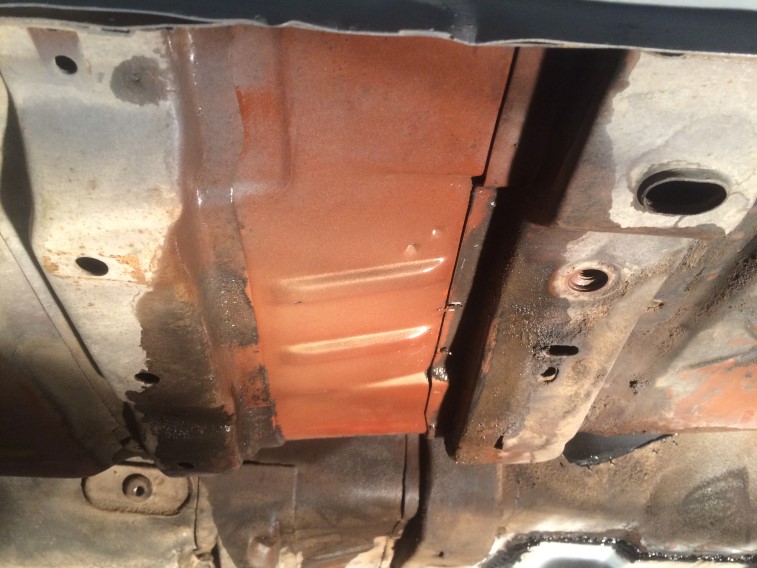

Did some work on the inner fender. The crack needed to be smoothed out with a hammer since it was kind of overlapping.

Still need to weld the crack on the inner fender.

Swapped out the brackets on the rotisserie for the rear (it was mounted on the leaf spring mounts with different brackets). Was nervous that the holes I had drilled out would match the bumper mounting holes – they did – woo-hoo!

Kept everything loose on the rotisserie after I put the car on jack stands.

I ended up using some grease on the bottom bars as they were difficult to slide. I had used the grease on the upright sections already:

Keep in mind, I am doing this myself. I was nervous about bumping the car off the jack stands as I lined things up. I ended up lining the front and back up, center bar in place (still loose), then used the subframe bolts to mount the front of the rotisserie to the subframe mounts:

I also blocked the wheels on the back end:

I had to go get some 3″ bolts (longer than what I had) and used some spare foam to protect the primer as shown below:

I then adjusted the pivot point in front to match the rear which is now higher. I am not sure if I will like this when I go to rotate – might re-adjust when I rotate the body.

I still have to tighten things up before lifting the car. Next steps is to weld the crack on the inner fender and take the car outside to power wash the bottom of the floor.