My shipment of 6 more cans of Zero-Rust arrived yesterday and since the weather is supposed to get cold in a couple of days, I got some more painting done. Just have five more pieces to do tomorrow!

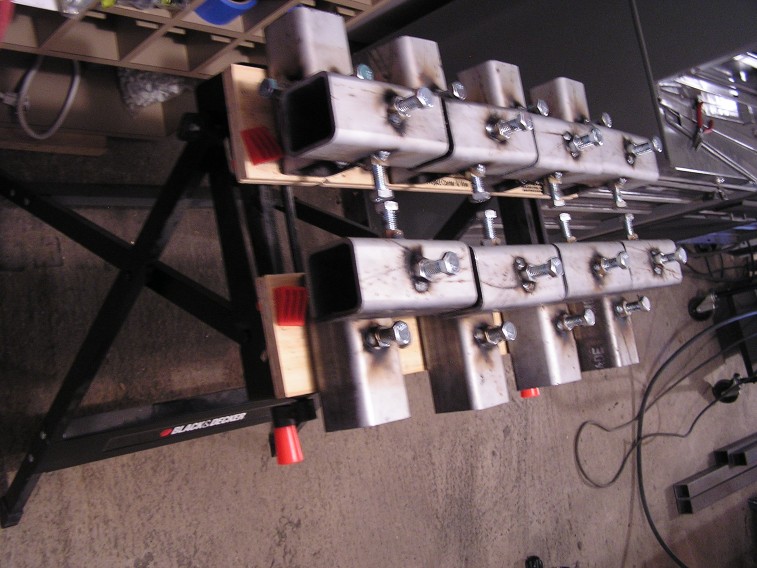

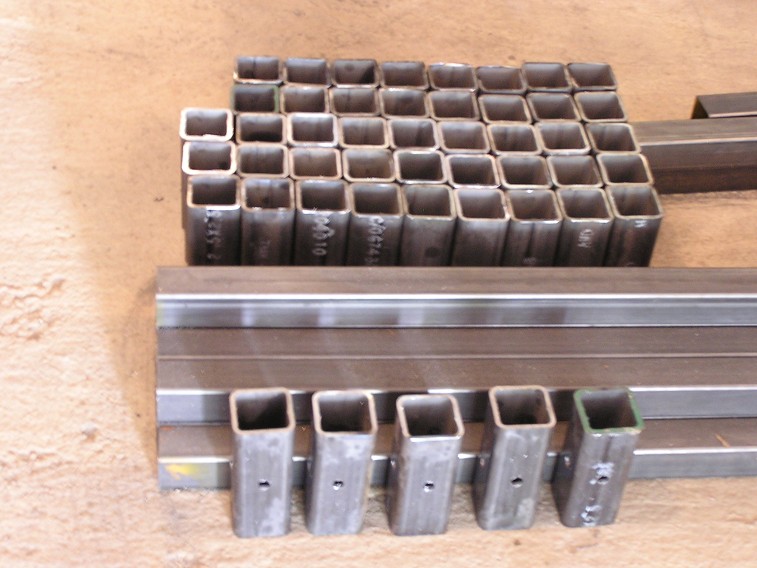

10 cross pieces 6″ 2.5″x2.5″

For the casters: 6″ 2×2 and 2 6″ 2.5×2.5

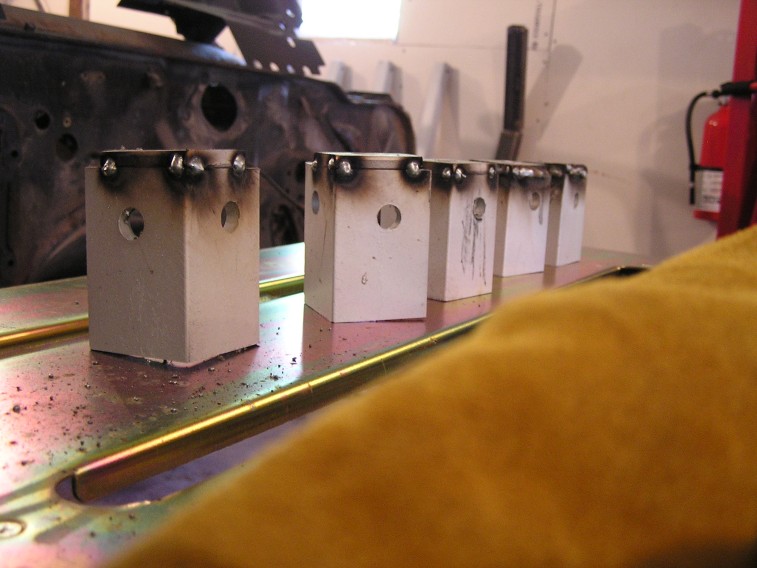

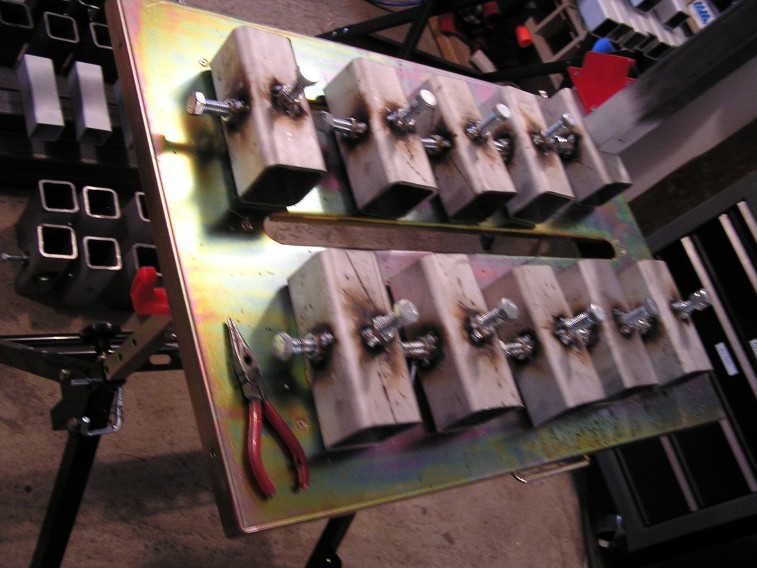

For attaching the car to the jig (various lengths):

2 @ 27″, 2 @ 23″, 2 @ 19″, 2 @ 16″, and 2 @ 13″

These are all that remain to be painted for the Jig: