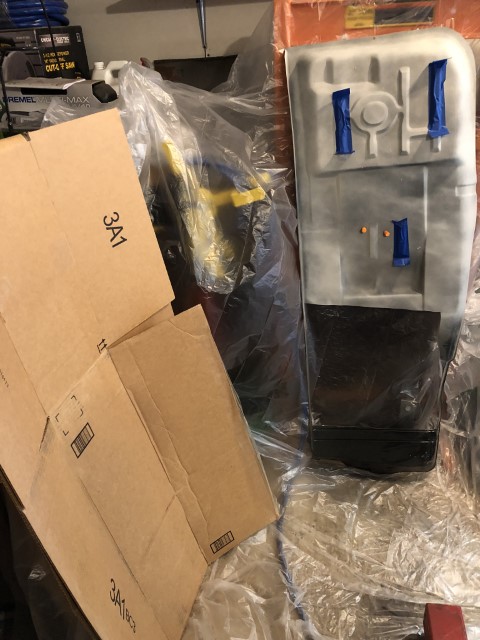

Undercoating is done! Using u-pol Raptor Bedliner. Day one: Taping and plugging holes: I needed to protect part of the rear frame rails for when I install the sub-frame connectors. There there were various screw holes where I either used cotton balls or ear plugs (for shooting).

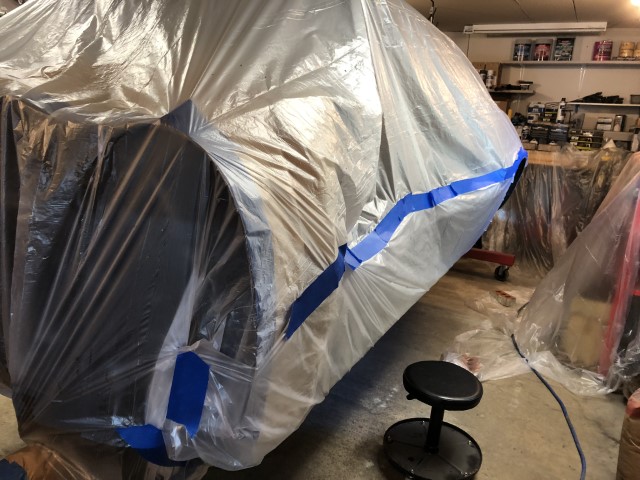

Then I used plastic painters drop cloths to protect the rest of the shell and I covered the floor and tools to protect from over spray.

Then I used plastic painters drop cloths to protect the rest of the shell and I covered the floor and tools to protect from over spray. The stars finally aligned and no more excuses to delay any further… The lighting isn’t the best and I will try to get better pics in a week once it is completely dried.

The stars finally aligned and no more excuses to delay any further… The lighting isn’t the best and I will try to get better pics in a week once it is completely dried.

There are a couple of small things I want to do while it is still on the rotisserie, but be winter it will no longer be on the rotisserie! Loki – my Norwegian Elkhound enjoyed the day supervising.

There are a couple of small things I want to do while it is still on the rotisserie, but be winter it will no longer be on the rotisserie! Loki – my Norwegian Elkhound enjoyed the day supervising.

I sprayed two coats with an hour between. Temp was about 70 and 60% humidity. I had a couple of fans going and the garage door open a jar for good air flow. I had 8 bottles and ended up using 5. I would do about half and start the other with a new bottle rather than go until the bottle is out. Less than an hour to spray, an hour flash and then less than an hour to spray second coat. I then waited an hour or so and removed the plugs and tape along with the plastic. Take your time and make sure you review that you have all plugs out.

I sprayed two coats with an hour between. Temp was about 70 and 60% humidity. I had a couple of fans going and the garage door open a jar for good air flow. I had 8 bottles and ended up using 5. I would do about half and start the other with a new bottle rather than go until the bottle is out. Less than an hour to spray, an hour flash and then less than an hour to spray second coat. I then waited an hour or so and removed the plugs and tape along with the plastic. Take your time and make sure you review that you have all plugs out.