The last couple of evenings have been spent rebuilding the steering shaft – there are some build threads, so I will just clarify a few parts where I struggled – first let me clarify I will be installing a tilt steering column for a 73 Camaro and it needs a specific shaft which differs from a non-tilt. For reference – the main source of information is: http://nastyz28.com/threads/steering-shaft-rebuild-process.92926/

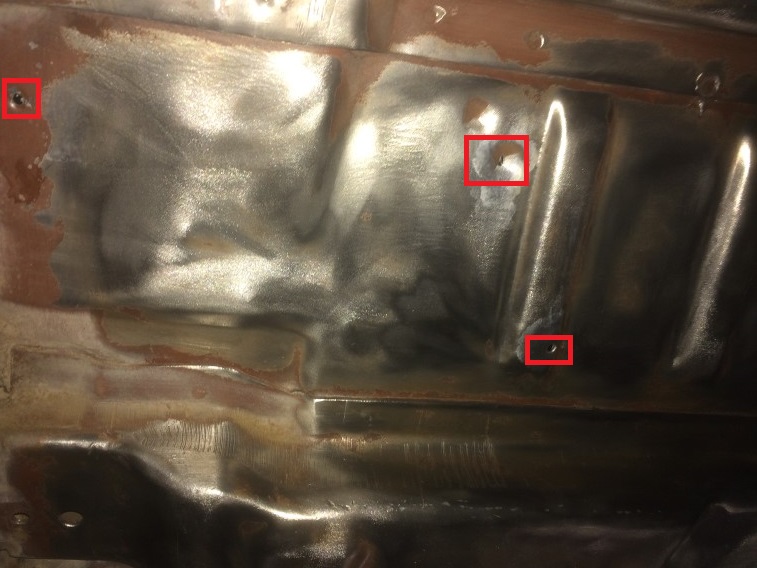

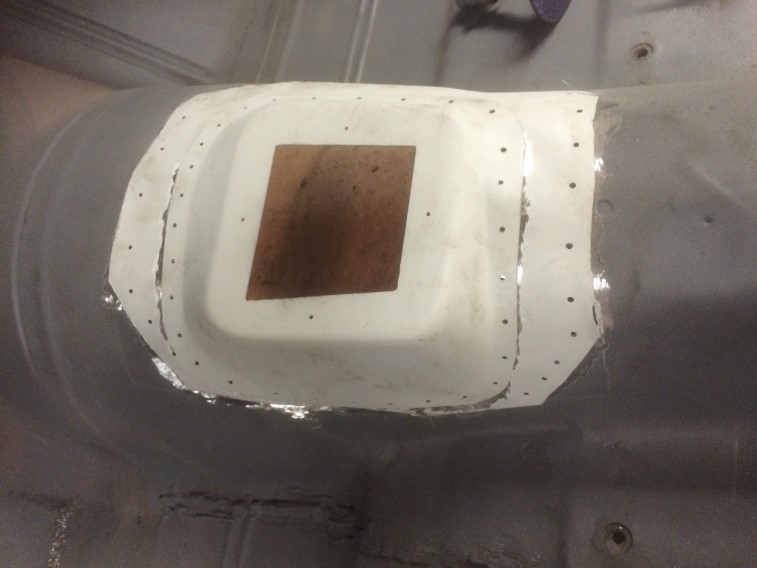

This is what I started with:

Notice the 2 clips on the housing to the right – once you straighten them out, there is a washer the unit has to slide over to come off. I needed a little persuasion to get it to come off, but managed to do it without any damage:

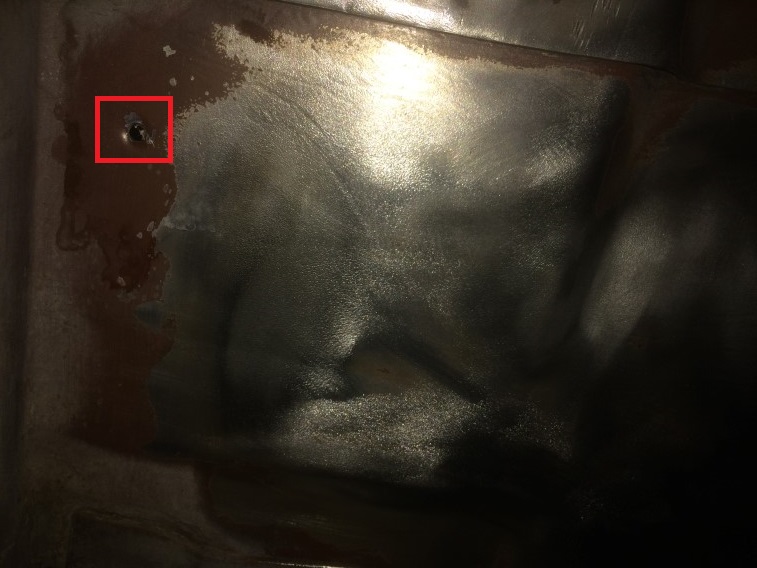

Now the early style has a pin to remove, this is not that style – I placed it in a vice and used a socket wrench extension to hammer out the smaller part: note the spring inside came out towards the cabinet – make sure the extension is as long or longer than the larger piece it is going in:

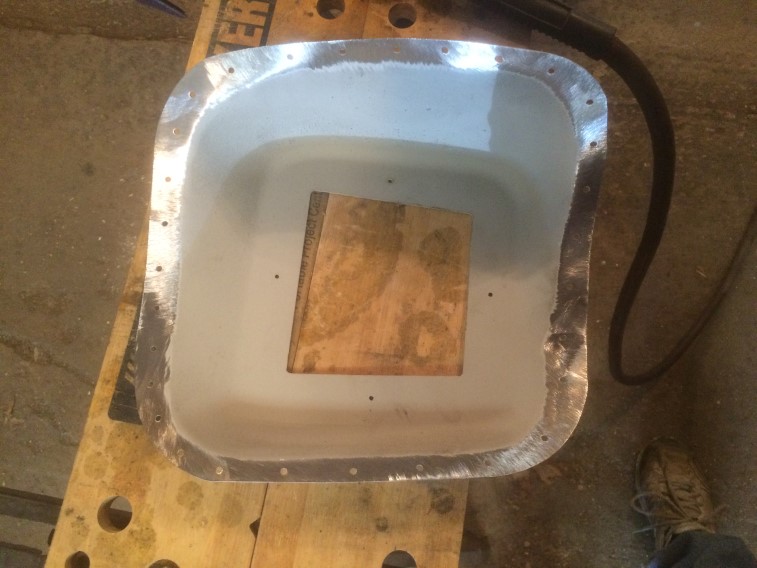

A reference pic for when I re-assemble it:

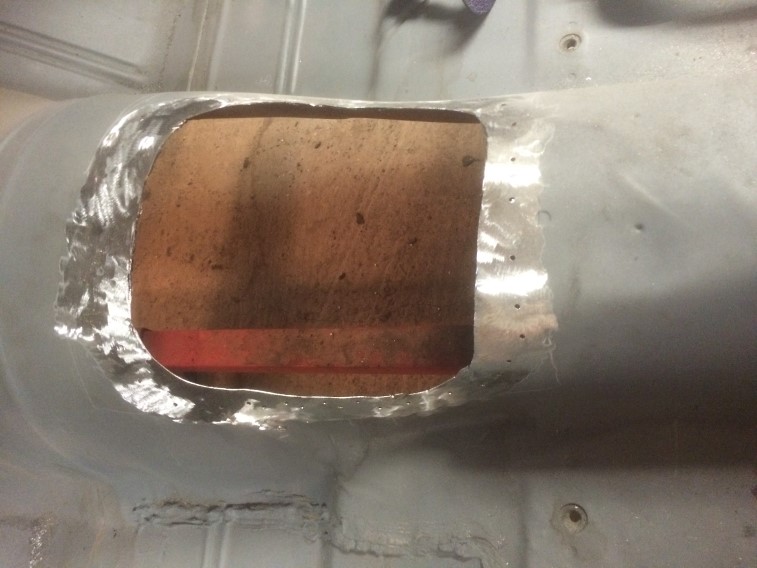

Note the spring that came off is completely a circle – the NOS replacement I have is not, but some trial fitting shows it should be ok:

Now to blast them with some remaining pieces from the subframe – then paint and re-assemble: