Completed the inside of the trunk. The POR-15 that I had used in the driver’s toe area has held up for 2 years so far, so I decided to use it again on the trunk.

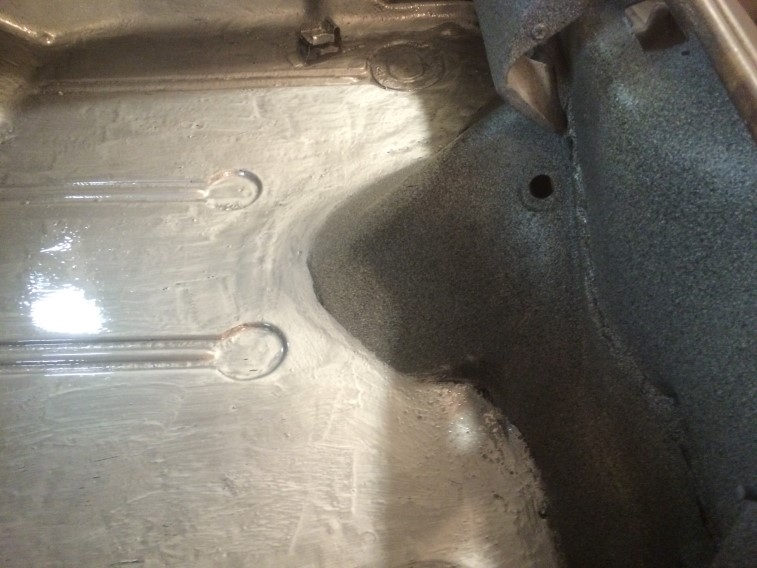

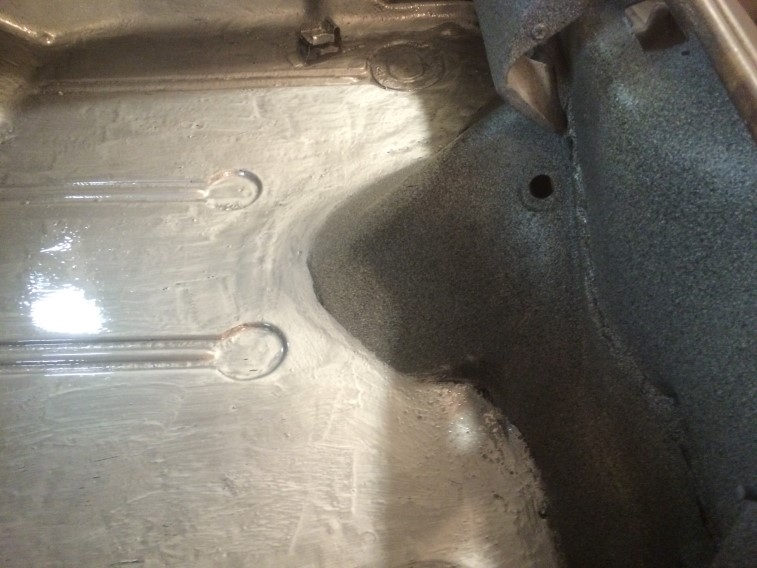

So this is what I started with. There were a couple small er than pencil size holes and some pitted metal, but for the most part, was in pretty good shape:

I got the por-15 Floor & Trunk kit along with por-patch and por-15 OEM bedliner. After scuffing the metal and using wax & grease remover to clean, I used the por-15 degreaser by spraying it on keeping it wet for 15 minutes then rinsing with a sponge and bucket of water. I then used the por-15 metal prep doing the same thing. I then waited overnight. I also ensured I had 3 nylon brushes which were discarded after each coat. I used por-15 Silver for the 1st coat:

Then por-15 Black for the 2nd coat:

Then back to por-15 Silver for the 3rd coat:

At this point, I used the por-patch to fill in the few small remaining holes using an acid brush to smooth it out.

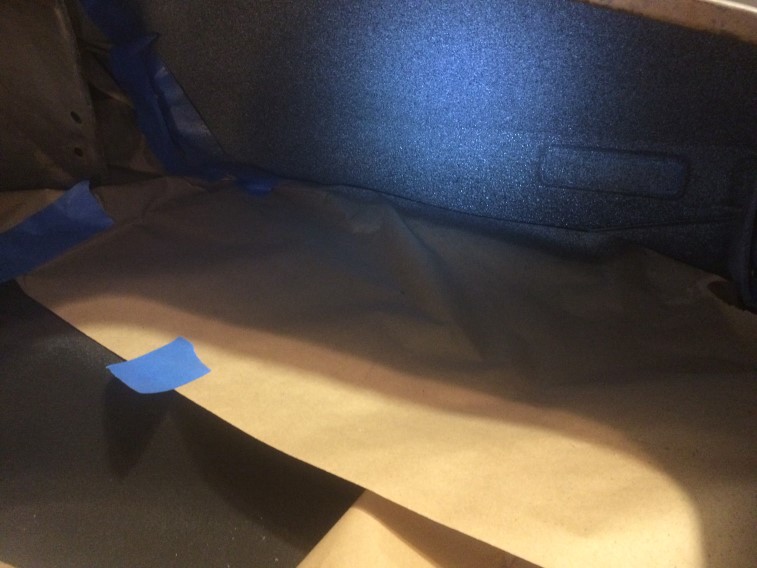

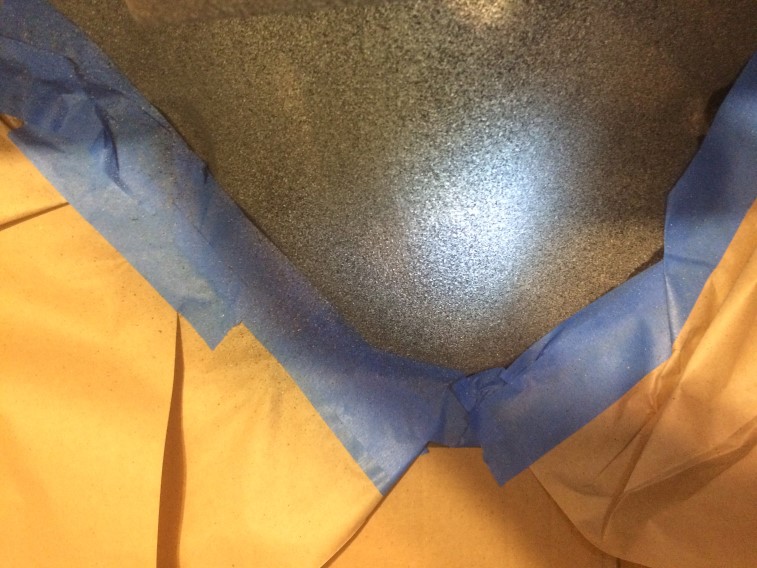

POR-15 OEM Bedliner 1st coat (rolled on)

POR-15 OEM Bedliner 2nd coat (rolled on)

Next morning:

Now I realize there are 2 different looking paint I used, but I plan on having a trunk mat in there, so the por-15 will be covered anyways.

DOH! There was a hole I had forgotten about and missed which should have been covered with the por-15 before the bedliner.

I ended up using the por-patch along with some of the mesh which came with the kit and pusing into the por-patch before applying more por-patch over it,

Final application (still wet)

I could have used the same paint over top of the por-15 instead of the bedliner, but the bedliner will be much stronger. Next will be the street side of the floor: epoxy, filler, and u-pol Raptor bedliner. I am already behind schedule of where I wanted to be at this point in the summer.